Why Use Desiccant Technology?

Dedicated desiccant air-supply units provide low-humidity conditions necessary to maintain a dry environment. It's a simple solution to an old problem.

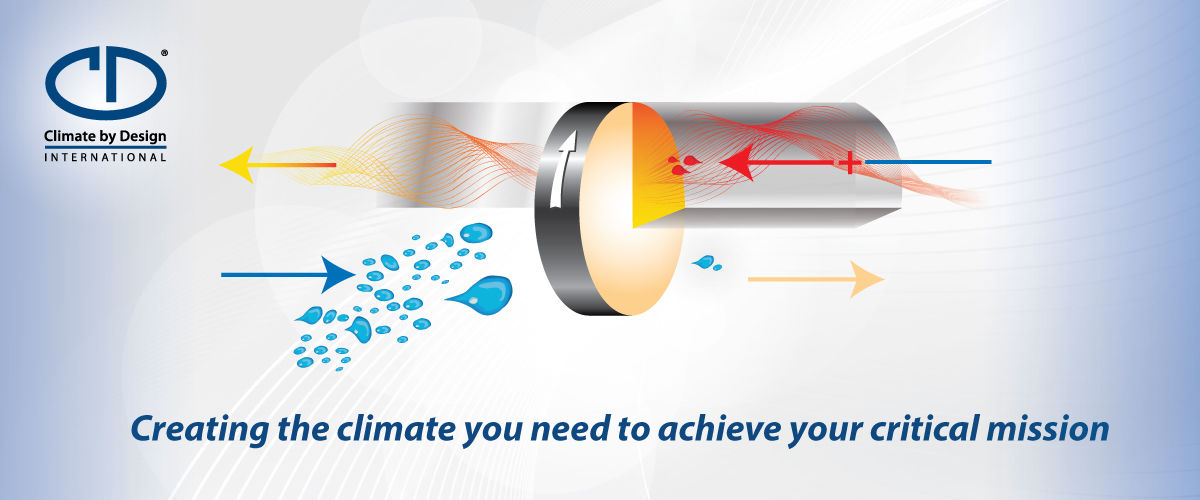

Desiccant Dehumidification is a continuous process. A desiccant wheel rotates through two separate airstreams.

The solid desiccant rotor adsorbs moisture from process air [1]. The moisture is taken out of the rotor by a second and separate reactivating airstream [2]. This process enables the rotor to continually take moisture out of the airstream without interruption.

Desiccant Dehumidification

Uncontrolled humidity does not need to be a problem. By providing dry desiccant air supply you can control threats to safety, product and costs. Dry air is a solution to corrosion, bacterial, mold, and mildew growth. You can have independent control of moisture levels and temperatures. Now you can be as dry as you want at whatever temperature you want.

Benefits of using Desiccant Technology:

- Very dry air can be achieved.

- Better thermodynamic efficiency: Achieved because no change of phase (condensation) is necessary.

- Simple Construction: Basic dehumidifier includes only two fans, a heater and the desiccant rotor assembly.

- Simple maintenance: Simply replace filters regularly and performance is assured. A yearly inspection by our service technicians is recommended to head off unscheduled outages.

- Better construction: Double-wall insulated casing suitable for indoor or outdoor mounting.

- Modern controls: We include standard intelligent microprocessor controllers with "Fail Capable"mode and full building integration capable of using BACnetTM, or Modbus®