Revolutionizing Spiral Freezer Operations in Frozen Food Production

The Problem:

Spiral freezers are essential for freezing products quickly and efficiently in frozen food production. However, moisture infiltration poses a significant challenge, leading to:

- Frost and Ice Buildup: Accumulating on conveyors, evaporator coils, and freezer openings.

- Frequent Defrost Cycles: Disrupting production and increasing energy consumption.

- Operational Hazards: Slippery surfaces, reduced worker safety, and compromised packaging quality.

- Vapor Pressure Challenges: Higher moisture levels in adjacent processing spaces push vapor into the freezer, forming ice even when air flows outward.

The Solution:

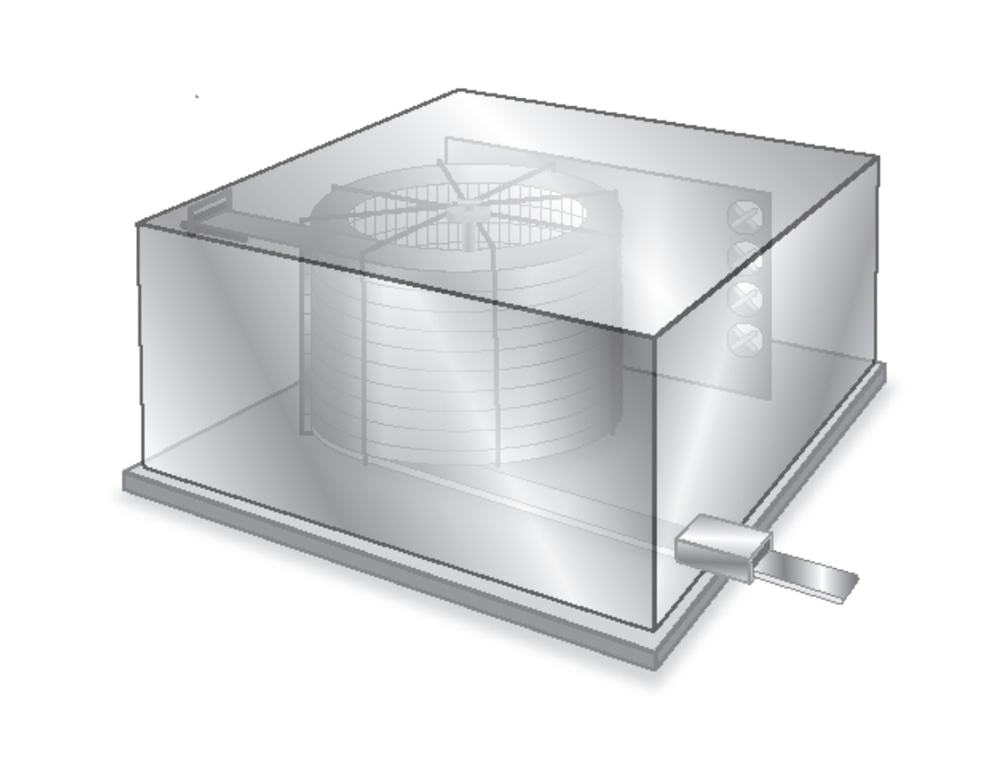

Climate by Design International (CDI) provides a robust solution using desiccant dehumidification. Our Dry Climate Series effectively lowers the dew point, preventing moisture infiltration and controlling vapor pressure around spiral freezers.

Key features include:

- Moisture Control: Removes up to 95% of moisture at the freezer entry point.

- Reduced Frost Formation: Creates a dry air “pillow” at freezer openings to prevent ice buildup.

- Improved Efficiency: Extends defrost cycles from multiple times a day to once a week in many cases.

- Energy Optimization: Shifts latent load management to the desiccant system, freeing evaporators to focus on cooling.

How It Works:

CDI’s desiccant systems operate with precision to target moisture at the source:

- Dry Air Distribution: Dry air is supplied to plenums at the spiral freezer’s entry and exit points, creating a moisture barrier.

- Low-Velocity Airflow: Maintains a dry zone around freezer openings, catching moisture before it enters.

- Vapor Pressure Management: Significantly reduces the differential between processing and freezer spaces, preventing moisture migration.

Benefits of CDI’s Solution:

- Extended Defrost Cycles: Keep freezers operational longer, reducing downtime.

- Improved Worker Safety: Eliminate slippery surfaces and enhance visibility by reducing fog.

- Enhanced Product Quality: Maintain consistent freezing conditions for better packaging integrity and reduced contamination.

- Lower Energy Costs: Optimize evaporator and cooling coil performance by shifting moisture management to the desiccant system.

Why Choose CDI?

At CDI, we understand the unique challenges of frozen food production. With decades of expertise and innovative solutions, we deliver systems tailored to your needs. Our desiccant dehumidifiers are designed for reliability, efficiency, and superior performance in critical environments like spiral freezers.

WEBINAR:

Spiral Freezers & Cold Storage Loading Docks

Are frost and ice driving up costs and slowing down production?

Discover how CDI’s desiccant technology can transform your operations by reducing frost and ice buildup, improving product quality, and extending production cycles. Whether you’re working with spiral freezers, tunnel freezers, or cold storage facilities, our solutions can help you achieve efficiency and cost savings through the power of dry air.

In this webinar, you will:

- Identify the root causes of moisture challenges in your cold storage facility.

- Explore solutions and benefits provided by CDI’s desiccant technology.

- Understand the specific challenges faced by spiral freezers.

- Learn how a cost-effective Dry Climate system can reduce defrost cycles and enhance productivity.

It’s time to eliminate frost-related headaches and enjoy the advantages of a drier, more efficient system. Join us to see how CDI’s innovative solutions can make a measurable difference in your operations.

Contact our Sales Engineers with your questions about these units at sales@cdihvac.com or see our Contact Us page.