DryDock Cold Storage Solution for Loading Docks

Eliminate Moisture, Enhance Efficiency, and Ensure Safety in Cold Storage Operations

The Problem

High humidity poses significant challenges in cold storage environments, particularly at loading docks where warm, moist air infiltrates during operations. The consequences are severe and costly:

- Fog and Condensation: Impairs visibility, reduces worker safety, and shortens product shelf life.

- Ice Buildup: Accumulates on floors, equipment, and ceilings, causing slippery surfaces, hindering conveyor and door operation, and damaging critical components.

- Increased Energy Costs: Frequent defrost cycles for evaporators strain refrigeration systems and raise utility bills.

- Moisture Migration: Driven by vapor pressure, warm air introduces excess humidity into cold storage areas, exacerbating condensation and ice issues.

Conventional solutions, such as strip curtains and air curtains, provide limited protection against moisture infiltration and fail to address the root causes effectively.

The Solution: DryDock Cold Storage Systems

DryDock desiccant dehumidification systems provide a targeted, high-performance solution for controlling humidity at cold storage loading docks. By capturing moisture at its source and supplying dry, dehumidified air, these systems ensure a safer, more efficient environment.

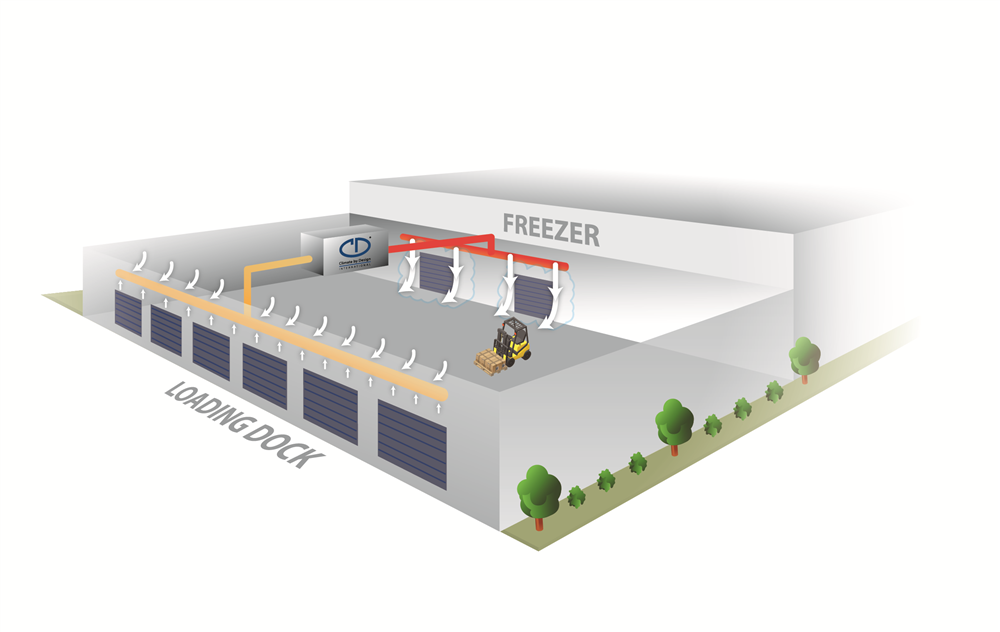

How It Works

- Advanced Desiccant Technology: Removes moisture from incoming air, achieving low dew points that traditional mechanical cooling cannot match.

- Strategic Air Distribution: Supplies dry air directly to loading dock entrances and freezer doors, creating a “dry air pillow” that minimizes moisture infiltration.

- Integrated Design: Complements existing refrigeration systems by shifting the moisture load to the desiccant unit, freeing refrigeration to focus on temperature control.

Key Benefits

- Enhanced Safety:

- Reduces fog and condensation, improving visibility for workers.

- Prevents slippery surfaces and minimizes risk of workplace accidents.

- Improved Operational Efficiency:

- Eliminates ice buildup on doors, conveyors, and evaporators, ensuring uninterrupted operations.

- Reduces downtime and maintenance needs caused by frequent defrost cycles.

- Lower Energy Costs:

- Shifts the latent load to desiccant systems, reducing strain on refrigeration.

- Enables energy-efficient operation with reduced defrost requirements.

- Prolonged Equipment Lifespan:

- Prevents ice-related damage to evaporators, fans, and other components.

- Flexible Deployment:

- Systems can be configured for specific facility layouts, targeting high-use dock doors for maximum effectiveness.

Why Moisture Control Matters

Challenges at Loading Docks

- Warm, humid air enters through open dock doors, creating significant vapor pressure differentials.

- This vapor pressure drives moisture deep into the facility, even when air curtains or strip curtains are used.

- Fog and frost form as moisture-laden air encounters cold surfaces, impacting safety and productivity.

Desiccant Dehumidification: The Superior Solution

- Unlike mechanical cooling, which freezes moisture at the coil surface, desiccants remove moisture before it can condense or freeze.

- DryDock systems consistently maintain dew points as low as 0°F, effectively preventing condensation and ice buildup.

Customer Success Story

“The unit on the loading dock at Nestlé has performed exceptionally well! Frost and ice have completely abated, and all the associated problems have gone away. We have a very happy customer in Nestlé.”

– Joe Daniels

Steps to Optimize Loading Dock Performance

- Inspect Dock Door Seals: Ensure all doors are properly sealed to prevent moisture infiltration.

- Stage Packaging Materials: Use low-humidity staging areas to dry out hygroscopic materials like cardboard and wood before they enter the cold storage space.

- Deploy DryDock Systems: Install desiccant dehumidifiers to capture moisture at its source and maintain low dew points near freezer entrances.

Proven Results

Facilities using DryDock systems report:

- Frost-free loading docks and freezer doors.

- Extended intervals between defrost cycles, reducing energy costs.

- Safer working conditions and improved visibility for employees.

- Reduced equipment wear and increased productivity.

Dry Dock Cold Storage Solution

WEBINAR:

Spiral Freezers & Cold Storage Loading Docks

Does frost and ice have your costs spiraling out of control? Is your production cut by defrost cycles? Learn how desiccants can be applied to reduce your costs, improve product quality and increase production. This applies to spiral and tunnel freezers. It’s time you start enjoying the benefits of dry air. In this webinar we will:

- Get to the root cause of the symptoms in your cold storage facility.

- Understand the solutions and benefits provided by CDI desiccant technology.

- Review the challenges of spiral freezers.

- See how applying a cost effective Dry Climate system can make all the difference you need.

Contact Us

Ready to eliminate humidity challenges in your loading docks?

Contact us today at sales@cdihvac.com or see our Contact Us page to learn more about DryDock Cold Storage or request a customized quote for your facility.