Unique Technologies

Benefits of Desiccant Drying

- Independent Control of Temperature / Humidity

- Reduced Air Flow due to Larger Grain Depression

- Enhances Indoor Air Quality by Lowering Duct RH%

- The Latent Load is Handled with Less Expensive Natural Gas or Steam

- Transfers Latent Capacity from Refrigeration

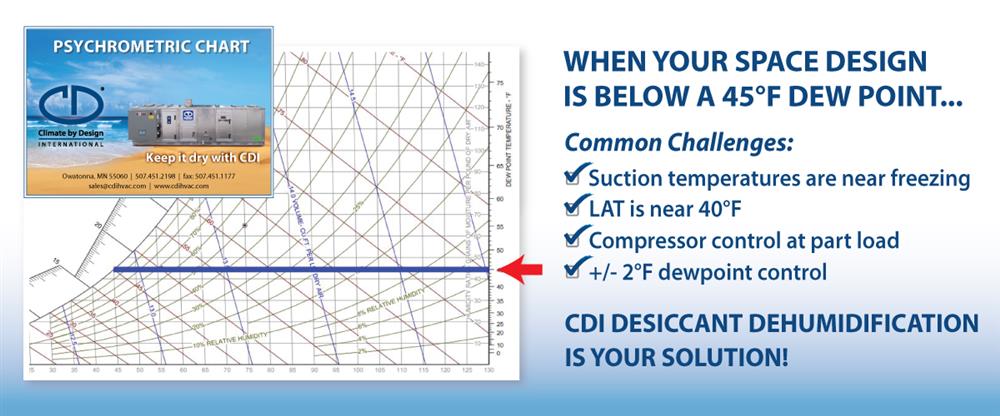

Why Use Desiccant Technology?

Dedicated desiccant air-supply units provide low-humidity conditions necessary to maintain a dry environment. It's a simple solution to an old problem.

Desiccant Dehumidification is a continuous process. A desiccant wheel rotates through two separate airstreams.

The solid desiccant rotor adsorbs moisture from process air [1]. The moisture is taken out of the rotor by a second and separate reactivating airstream [2]. This process enables the rotor to continually take moisture out of the airstream without interruption.

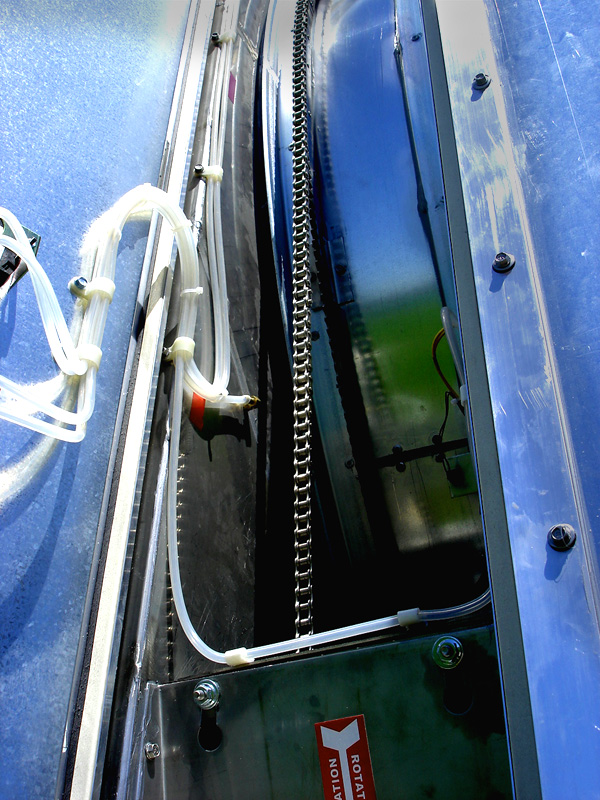

Desiccant Rotor System Built to Last

Rotor: Stabilized silica gel is permanently bonded to a low specific-heat substrate for long-lasting dehumidification performance at maximum efficiency. The desiccant rotor rim and cassette are stainless steel for durability and strength. | ||

| Chain: A full-perimeter sprocket with a #40 molly chain drives our desiccant rotor making it more durable than any other system on the market.

| |

| Seal: CDI desiccant rotor seals are dual-contact, extruded seals, designed to last for the life of the unit. This is the most durable seal in the industry. |

NTM™ (No Thru Metal)

CDI NTM™ (No Thru Metal) Thermal Break Air Handler Cabinet

|  |  |

When thermal performance is critical and cabinet condensation cannot be tolerated, CDI has the solution.

All air handlers that produce cold air need to be insulated. Air handlers utilizing double wall construction for interior cleanliness place the insulation between the inner and outer skins of the unit, which are in intimate contact with one another. Without a thermal break between the interior and exterior surfaces, exterior surfaces of the system can become cold, often resulting in condensation or "sweating" on the outside of the unit.

UVGI

What Air Handling Applications can benefit from UVGI?

- Food Processing

- Pharmaceutical

- Laboratories

- Schools

- Offices

- Hospital

UVGI stands for Ultraviolet germicidal irradiation. Simply put, it refers to exposing micro-organisms to ultraviolet radiation in the range of 200-280nm, known as Ultraviolet C Band, or UVC. As a result, the micro-organisms are killed or sterilized to keep it from reproducing.

Reactivation Heat Recovery

Increased Energy Efficiency

Energy costs continue to climb, CDI has solutions to reduce those costs. Our standard DDC control systems hold energy usage to minimum levels. Energy use can be further reduced by recovering heat from the reactivation outlet air stream. That moisture laden air stream holds a lot of energy that can be captured through this well designed system. The core device is a sensible plate heat exchanger that does not allow moisture transfer to the reactivation inlet air stream. Temperatures of the reactivation airstream cool to condensing levels. The sensible plate heat exchanger is contained in an all inner lined stainless steel chamber to wring out your energy dollars and provide long life in this extremely wet environment.

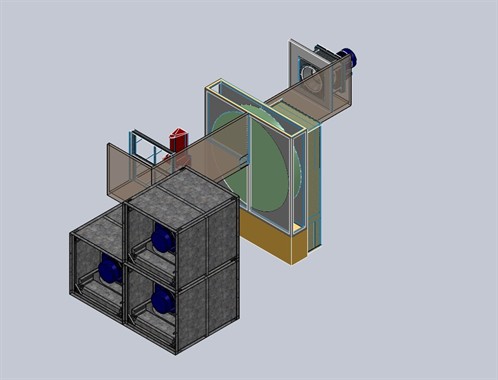

Fan Brigade™

- Multiple fans for high reliability and redundancy

- Direct Drive for higher reliability. No belt maintenance

- Smaller fans for ease of maintenance

- Small footprint

- Favorable sound profile

- Aluminum wheel for low vibration and long bearing life

- Modular Design

- Tetris-like installation flexibility

- Sizes 12" to 40" available

- Up to 12" w.g. static pressure

- VFD Driven

Technology

CDI has invested heavily in technology since its inception. Our projects are designed utilizing internally developed "Climate by Design" software. This software program is used by our sales engineers and associates to configure and predict the performance of an air handling unit.