Critical Process Air Handling

What Does the Critical Process Rooftop (CPRT) Series Do?

- Provides room pressurization to control or elimate issues with uncontrolled air infiltration from unconditioned areas.

- Provides conditioned air to the room temperature and humidity specifications.

- Provides air filtration to ensure product quality.

- Sanitary unit casing design constructed with smoother, flattter surfaces that can be sanitized.

- Reduced catch points for mold, bacteria and other microbial growth.

.jpg)

Keep in Compliance at All Times with our CPRT Series!

Moisture can cause mold, mildew, and other microbial issues. Building codes require energy intensive use of outside air. Uncontrolled, airborne contaminants can negate your food and product safety strategies. Extended clean up recovery times limit valuable hours each day that should be available for production. The Critical Process Rooftop series is sized and configured so you stay in control. Keep the air that circulates through production areas clean, dry, and properly conditioned.

Critical Process Rooftop Series (CPRT)

- Process air flow range of 2,000 to 100,000 SCFM.

- Designed with pre-configured components combined to meet unique project requirements.

- Total system integration available including heating, cooling, and special filtration including controls.

- Any room or ambient conditions can be addressed by the CPRT's capabilities, while having the capability for full washdown.

Standard G-90 Galvanized Steel or optional 304 Stainless Steel Floors are formed and welded into IAQ style drain pans. Each drain pan connection drains to the exterior for full wash down capability. You can choose the necessary construction materials to match your cleaning solutions compatibility.

Ultraviolet Germicidal Irradiation, simply put, it refers to exposing micro-organisms to ultraviolet radiation in the range of 200-280nm, known as Ultraviolet C Band, or UVC. As a result, the micro-organisms are killed or disabled from reproducing.

Contact our Sales Engineers with your questions about these units at sales@cdihvac.com or see our Contact Us page.NTM™- NoThruMetal

CDI's patented NTM™ (NoThruMetal) cabinet is truly a "cabinet within a cabinet" with pressure-injected, expanding polyurethane foam insulation and no metal fasteners or thermal bridging. Even the structural members in the unit base frame connecting the inner (cold) surfaces to the outer (warm and wet) surfaces do not have through metal or the opportunity to condense.

The result is truly thermally broken unprecedented thermal performance that dramatically increased resistance to air and moisture leakage and provides superior condensation control.

Drain Pan Style Floor

Standard G-90 Galvanized Steel or optional 304 Stainless Steel Floors are formed and welded into IAQ style drain pans. Each drain pan connection drains to the exterior; for full wash down capability. You can choose the necessary construction materials to match your cleaning solutions compatibility.

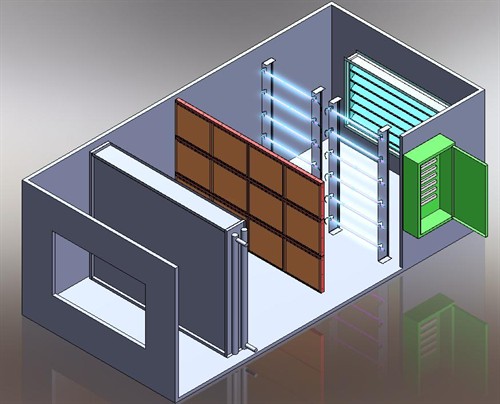

UVGI - Ultraviolet Germicidal Irradiation

Ultraviolet Germicidal Irradiation, simply put, it refers to exposing micro-organisms to ultraviolet radiation in the range of 200-280nm, known as Ultraviolet C Band, or UVC. As a result, the micro-organisms are killed or disabled from reproducing.

WEBINAR TRAINING:

Critical Process Rooftop Food Processing Applications

Looking for another viable option to keep the air that circulates through your production areas clean, dry, and properly conditioned? Born from a King, CDI’s Critical Process Rooftop series is sized and configured so you stay in control. Any room or ambient conditions can be addressed by the CPRT’s versatility, while having the capability for full wash-down.